The exponential growth of photovoltaics in Spain is a key pillar of the energy transition.1 However, this rapid deployment brings with it the need for rigorous analysis of the operational risks inherent in utility-scale assets. Recent incidents, such as the fires at plants in Cáceres and Badajoz that affected hundreds of hectares, have highlighted not only the risk of asset loss, but also the impact on public safety and the social perception of the industry.2

For Operation and Maintenance (O&M) managers, preventing these low probability but high severity events is a critical challenge. A detailed analysis reveals that most fires are not random events, but the consequence of progressive failures that emit detectable warning signals long before an ignition occurs.

Root Cause Analysis of Photovoltaic Incidents

Although PV technology is inherently safe, insurance industry data and failure analyses converge on a clear set of root causes that precede most fires. These can be categorized as follows:

- Installation and Component Quality Errors: They constitute the leading cause of claims. Industry reports attribute up to 37% of fires to errors during the installation phase and 35% to product defects.5 Practices such as incorrect crimping of connectors, improper tightening torque on screw terminals, or the use of low quality components (cables, connectors, etc.) introduce high electrical resistance points into the system.6

- Material degradation: Over time, exposure to UV radiation and thermal cycling degrades cable insulation materials and module backsheets.7 This degradation compromises dielectric insulation, creating avenues for short circuits or current leakage.

DC Arc Fault: The Fire Catalyst

The physical mechanism that transforms these latent defects into a fire is, in most cases, the direct current (DC) arc fault. Unlike an AC arc that can self-extinguish when it crosses zero, a DC arc is self-sustaining as long as there is solar irradiation, generating temperatures that can exceed 3,000 °C.

This phenomenon occurs when a poor connection degrades to the point of physical interruption, or when the insulation between two conductors of opposite polarity fails.9 The resulting arc is a powerful and persistent ignition source, capable of melting metal and igniting surrounding materials.

Limitations of Reactive Detection Approaches

To mitigate this risk, modern inverters incorporate Arc Fault Detection Devices (AFCI/AFDD).10 These systems are crucial and mandatory in many regulations, as they monitor electrical noise in the circuit to detect the “signature” of an arc and shut down the inverter within milliseconds.

However, their function is inherently reactive: they act once the arc has already formed. While they may prevent the spread of fire, initial ignition may have already occurred. Therefore, a complete risk management strategy cannot rely solely on the final electronic protection.

Predictive Maintenance as a Proactive Mitigation Strategy

The missing link between a latent defect and an electric arc is a gradual heating process. A high resistance connection, before dropping catastrophically, generates heat through the Joule effect. This overheating is a process that can last for weeks or months, creating an anomalous “hot spot” in the system.

This heat is invisible to a visual inspection, but is perfectly detectable by infrared thermography. The implementation of a program of periodic thermographic inspections allows:

- Identify Failure Precursors: Detect connections, cables or components that operate at an abnormally high temperature compared to similar elements in the same conditions.

- Act Preventively: Correct the underlying defect (e.g. retighten a connection or replace a defective connector) before degradation progresses to the point of arcing.

While thermography cannot predict sudden failures (e.g. animal damage or instantaneous mechanical breakage), it can identify the vast majority of problems that develop progressively. Considering that installation errors and component degradation are the main causes, it is estimated that a comprehensive and regular visual and thermographic inspection program could prevent 70% to 90% of potential fires.

Towards a New Standard in Photovoltaic Asset Management

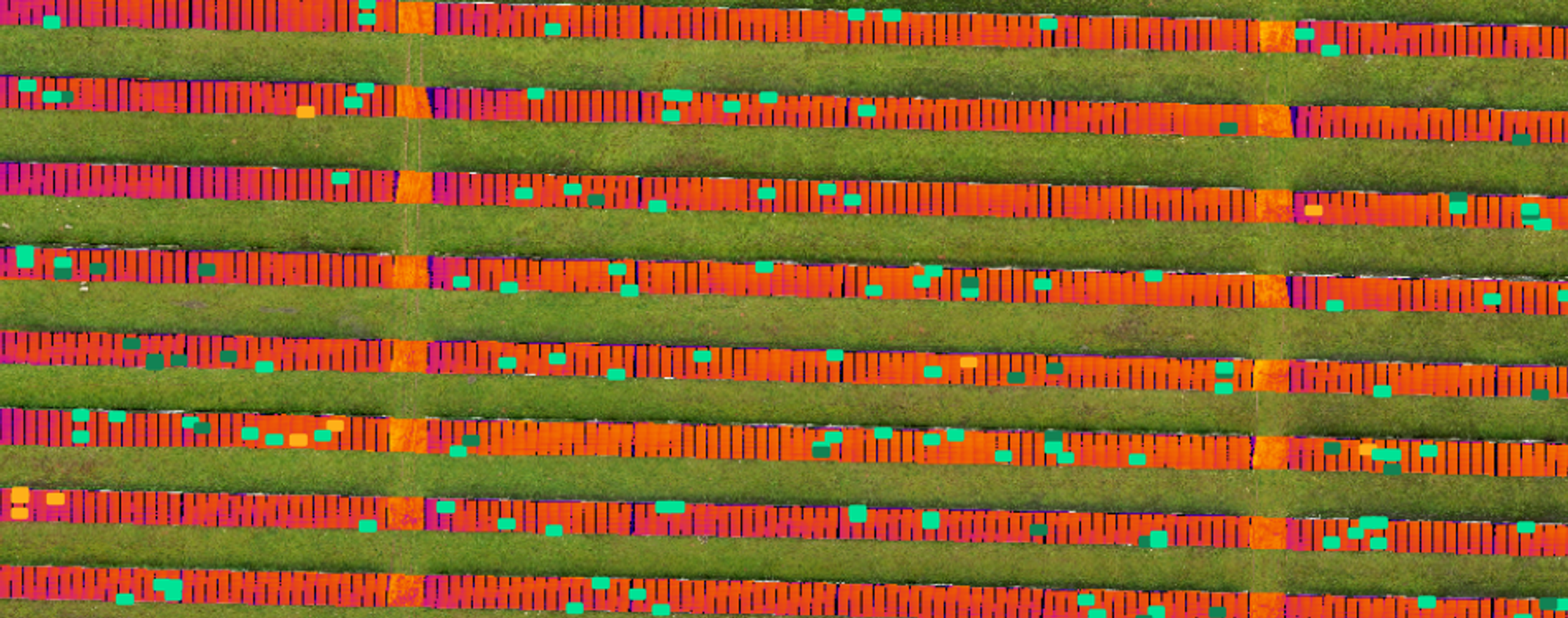

Risk management in large-scale PV plants requires an evolution from a purely corrective or reactive model to a predictive one. The integration of systematic thermographic inspections, facilitated by technologies such as unmanned aerial vehicles (drones) for efficient coverage, should not be seen as an additional cost, but as a strategic investment in asset resilience and operational safety.11

Anticipating failures before they occur not only protects the investment and ensures continuity of production, but also safeguards the reputation of the plant and the PV industry as a whole, reinforcing its role as a truly safe and clean source of energy.

Sources and related content

- https://www.mapa.gob.es/dam/mapa/contenido/agricultura/publicaciones/informeprospectivoagrivoltaica2023.pdf

- https://arsolaronline.com/incendios-solar/energia-solar-fotovoltaica/

- https://revistajaraysedal.es/incendio-huerto-solar-placa-fotovoltaica/

- https://www.pv-magazine.es/2025/08/25/un-fallo-electrico-en-una-planta-fotovoltaica-provoco-el-incendio-forestal-de-casas-de-don-pedro/

- https://material-electrico.cdecomunicacion.es/opinion/lorenzo-tasso/2024/07/31/desmontando-estigmas-verdad-tras-incendios-instalaciones-fotovoltaicas

- https://elperiodicodelaenergia.com/mas-de-1-000-incendios-se-produjeron-en-instalaciones-fotovoltaicas-en-los-ultimos-dos-anos/

- https://www.iberext.com/actualidad/principales-causas-de-incendios-en-sistemas-fotovoltaicos/

- https://viox.com/es/what-causes-solar-panels-to-catch-fire/

- https://www.acsolarwarehouse.com/blog/news-7/solar-fires-dc-arc-faults-224

- https://www.youtube.com/watch?v=owhrpnd6Qks

- https://material-electrico.cdecomunicacion.es/fotovoltaica-autoconsumo/174791/incendio-talavan-caceres-originado-planta-fotovoltaica